The 15th International Needle Coke and Carbon Materials Technology and Industry Development Summit (INCC)was successfully held from November 13 to 15, 2024, at the Hilton Green Tree Hotel in Kunming Airport. Organized by ICCSINO, the forum attracted carbon industry-related enterprises, experts, scholars, and industry elites from all over the country to gather and discuss technological innovation and development paths in the field of needle coke and carbon materials.

On the 13th, participants arrived for registration all day, signing in and collecting conference materials. On the eve of the official conference, representatives seized the opportunity to engage in in-depth exchanges and interactions.

At the registration desk, participants stopped to chat, sharing the recent developments and future plans of their respective companies. They exchanged greetings, engaged in heated discussions, and newcomers to the forum eagerly sought advice from seasoned veterans, looking to learn from their experience.

Subsequently, Mr. Pang Long, Deputy General Manager of Jilin Carbon Co., Ltd., representing the China Carbon Industry Association, and Mr. Sun Qing, Honorary Vice President, delivered speeches. Mr. Pang noted, "The carbon industry faces complex internal and external environments and pressures. However, overall, the high-quality development of China's carbon industry is accelerating, and the goal of advancing from a carbon power to a carbon leader is within reach." He encouraged the guests to actively share their research results and practical experiences during the forum to jointly promote technological progress and industrial upgrading in the carbon industry.

During the following agenda, Mr. Pang Long presented a keynote speech titled "Analysis of the Current Situation and Prospects of the Carbon Industry under the New Situation." He reported the economic indicators of the carbon industry for 2023 and the first nine months of 2024: the total production of carbon products increased by 1.62% year-on-year, with graphite electrodes and prebaked anodes increasing by 15.75% and 2.16% respectively. However, the industrial output value of the entire carbon industry decreased by 18.76% year-on-year during this period. Upstream and downstream production and operation in the carbon industry also faced significant challenges, with low operating rates and production cuts or partial shutdowns becoming the norm.

He concluded with three points: First, the carbon industry faces many challenges and pressures in the current complex and changing international situation but also new development opportunities. Second, the carbon industry needs to strengthen technological innovation, improve product quality and competitiveness to cope with market changes and competitive pressures. Third, the promotion of the dual carbon goals will bring new growth points to the carbon industry, which should actively respond to national policies and promote industrial transformation, upgrading, and high-quality development.

Following this, Huang Jingxin, Deputy Director of the Research Institute at Shanghai Shanshan Technology Co., Ltd., shared valuable experiences on "Exploring the Establishment of an Intelligent System for Anode Material R&D," providing new perspectives for the participants. He pointed out that with the booming new energy industry, the anode material sector faces unprecedented opportunities and challenges. However, the industry is under dual pressure of increasing production and declining profits, with homogeneous competition severely eroding profit margins. To address this dilemma, the industry is strengthening technological innovation, accelerating research and development in fast charging technology, energy density enhancement, and cycle performance optimization to stand out in the fierce market competition.

Facing the intense competition and accelerating technological iteration in the anode material industry, Huang Jingxin proposed the vision and planning for an intelligent R&D system in his report. He emphasized that by establishing an intelligent R&D system, a deep understanding of the structure-performance relationship of anode materials can be achieved, allowing for precise product development plans and improving R&D efficiency and quality. Additionally, the intelligent system supports the R&D of emerging systems, such as double-layer coated products, providing more innovative solutions for the new energy industry.

Shanshan Technology has taken solid steps in this direction. The company has invested heavily in establishing a basic research platform equipped with advanced testing equipment and R&D facilities to support intelligent R&D. Furthermore, the company is actively exploring intelligent pathways for raw material R&D, utilizing AI models to study complex compositions and achieve intelligent prediction of product parameters and process optimization.

Liu Weikai, Minister from Datong Xincheng New Material Co., Ltd., delivered a keynote speech titled "Analysis of Market Trends for Special Carbon Materials." In his speech, he highlighted the situation of isostatically pressed graphite. By September of this year, according to incomplete statistics, China's isostatically pressed graphite capacity has neared 400,000 tons. The current total capacity ranks first globally. Solar photovoltaic industry, electrical discharge machining, machinery manufacturing, petrochemicals, metal continuous casting, cemented carbide, glass manufacturing, aerospace, nuclear graphite, and military industrial isostatically pressed graphite have all achieved localization substitution.

Professor Cai Xiaolan from Kunming Haichuangxing Technology Co., Ltd. and Kunming University of Science and Technology shared insights on "Research on Multifunctional and High-Efficiency Powder Preparation Equipment and Lithium-ion Battery Silicon-Carbon Anode Materials."

In her speech, she pointed out that multifunctional and high-efficiency powder preparation equipment is one of the most advanced and efficient equipment for the preparation of specialty ultrafine/nano metal and alloy powders, as well as mechanochemical synthesis and alloying, both domestically and internationally. It addresses the shortage of high-end equipment for powder metallurgy, new energy materials, and metal-based composite material preparation. The adoption of dry and short-process technology for the preparation of lithium-ion battery cathode and anode powder materials represents a new technology that is superior to existing processes in terms of process and equipment, offering "short process, high efficiency, and low cost."

Li Xinyi, Deputy General Manager of China Kunlun Engineering Co., Ltd., delivered a keynote speech titled "Needle Coke and Complete Set of Technology for Closed Coke Removal."

Li Xinyi pointed out that the current closed coke removal technology faces issues such as high costs, long dehydration times, severe corrosion, and large volumes of VOC emissions. Therefore, the National Development and Reform Commission and other three ministries and commissions have issued guidelines requiring new delayed coking units to be equipped with closed coke removal facilities and accelerating the closed retrofitting of existing open units. In 2019, the Liaojin Branch designed the country's first tank-type closed coke removal project and developed a forced dehydration technology for closed coke removal in delayed coking units, achieving simultaneous coke removal, transportation, and dehydration. This solved the problem of excessively long dehydration times in existing passive dehydration technologies. At the same time, anti-clogging and backflush nozzles were developed to solve the issue of overflow ports being easily clogged by coke dust. The complete set of technology for closed coke removal (CCTS) in delayed coking units has passed the process package review organized by the China Petroleum Engineering Construction Association. It will be first industrially applied in the project to convert the 1-million-ton/year delayed coking unit of Jinzhou Petrochemical Company into a needle coke unit, with plans to commence production in late November 2024.

Zhang Chao, Sales Supervisor of Shandong Lianhua New Material Co., Ltd., shared insights on "Increasing Substitutes for Anode Raw Materials and the Path Forward for Needle Coke."

In his speech, he mainly introduced the supply and demand situation, price fluctuations, application fields, future demand outlooks, and strategies for needle coke enterprises.

He predicted that by 2028, needle coke capacity will reach 4.79 million tons. The demand for needle coke continues to grow, with an expected total demand of 2.19 million tons by 2028, including 690,000 tons in the graphite electrode sector and 1.5 million tons in the anode sector. In the future, with economic recovery, the growth rate of needle coke demand will resume, but with the trend of reducing needle coke usage in anode materials, the growth rate will be lower than previously expected.

He pointed out that domestic overcapacity is a serious issue, competition is intensifying, and smaller, weaker, and technologically backward enterprises will gradually be eliminated by the market. Therefore, needle coke enterprises should adhere to the following three points: firstly, quality is king, improving product quality and stability; secondly, enduring the "extreme cost reduction" challenge across the entire supply chain, increasing the added value of by-products, and optimizing the decoking and crushing processes; thirdly, "deeply cultivating" technological innovation to open up new horizons, establishing a comprehensive database for selecting raw materials that match pretreatment equipment and processes, and producing stable needle coke raw materials based on different raw material properties; fourthly, achieving customized production to meet different demands; and fifthly, focusing on the research and development of new products to empower anode customers.

Chen Dezhi, Deputy General Manager of Hengyuan Carbon Materials Co., Ltd., delivered a keynote speech on "The Current Situation and Future Opportunities of the Overseas Needle Coke Market".

He noted that the growth of overseas needle coke production capacity has been slow. Facing uncertainties in medium to long-term market demand, as well as shortages of raw materials and labor, foreign enterprises have been cautious in investing in needle coke projects and expanding production capacity. As a result, overseas needle coke production capacity has remained stable at around 1.05 million tons per year in recent years. With the development of overseas renewable energy markets and restrictions imposed by the international political situation, overseas needle coke enterprises will also begin to enter the stage of new construction and expansion. Currently, the main expansion plans are in the United States, while new production capacity is planned in Saudi Arabia and Russia. It is estimated that by 2027, overseas oil-based needle coke production capacity will increase by 300,000 tons. With the development of global new energy vehicles, there is also the possibility of expanding needle coke production capacity in South Korea and Japan in the future.

In the afternoon session, Mr. Lin Xiangang, Head of the Industry Research Department at the Sichuan Iron and Steel Association, was the first to speak, delivering a keynote speech on "The Current Situation and Development Trend Outlook of the Southwest Iron and Steel Industry".

He predicted that China's crude steel consumption will slightly decline or remain flat in 2025, with crude steel production controlled at 1.0 to 1.01 billion tons or less, and the overall supply and demand relationship in the domestic market will maintain a basic balance. In 2025, steel prices will generally fluctuate around the industry's average cost line, with both average prices and amplitude lower than in 2024. The southwest iron and steel industry faces challenges such as resource shortages and supply-demand imbalances, but it still has broad development prospects. By adjusting product structures, developing high-value-added products, strengthening market coordination and policy guidance, the southwest iron and steel industry will be promoted to achieve high-quality development.

Sun Jiyun, Deputy Director of the Carbon, Magnesium, and Titanium Business Unit at Guiyang Aluminium Magnesium Design & Research Institute Co., Ltd., shared insights on "Research on Energy-Saving and Carbon-Reduction Technologies for Graphitization Production of Anode Materials".

He pointed out that in the existing graphitization furnace core area, through reasonable production process operations and control, the furnace loading capacity of the graphitization furnace can be increased, and the crucible lifespan can be extended, thereby reducing the unit consumption of products.

Compared to traditional dense loading processes, the new process employs precise power delivery curve temperature control, optimized furnace core cooling processes, and coupling of furnace temperature, pressure, and time. Through relevant detection and control methods, it solves issues such as crucible oxidation, resistance material sticking to the crucible, arcing, and substandard quality, and extends the average lifespan of crucibles to more than five uses.

Shen Jianfeng, Deputy General Manager of Shandong Jingyang Technology Co., Ltd., delivered a keynote speech titled "Facing the Sun, 'Coking' Through to the Future".

He pointed out that the needle coke market is experiencing a situation of rapid capacity expansion but limited growth in actual demand, resulting in low overall operating rates in the market. However, oil-based needle coke still occupies an important position in the market due to its high-end market share and product quality advantages. Jingyang Technology is a leading enterprise in the domestic needle coke market, with stable supplies of needle coke products to both domestic and international markets. In the first three quarters of 2024, Jingyang Technology was the only needle coke producer with a 100% operating rate, and its export volume is expected to reach 18,000 tons for the whole year, accounting for a significant proportion of total exports.

Liao Hu, Deputy Director of the Research Institute at Shandong Yida New Material Co., Ltd., delivered a keynote speech on "The Current Situation of the Needle Coke Industry and the Transformation of New Production Capacity".

In his speech, he noted that in 2024, the new production capacity of the needle coke industry totaled 2.025 million tons, but the average capacity utilization rate was only 26%, indicating overcapacity. At the same time, due to factors such as low production enthusiasm among suppliers, declining production, stable demand for graphite electrodes, increased scheduling by anode enterprises, and an increased proportion of petroleum coke, needle coke prices have fluctuated to some extent. In the future, the needle coke industry will pay more attention to product quality, cost control, and changes in market demand to achieve sustainable development.

Industry expert He Peng shared insights on "A Review of the Development History of the Needle Coke Industry and Exploration of Future Development Paths".

He reviewed the historical evolution of the needle coke industry both overseas and in China, pointing out that the needle coke industry has gone through stages from its origin to a global investment boom, and now to a period of significant development in China's needle coke industry. Facing the difficulties encountered by overseas enterprises, Chinese enterprises need to continuously innovate and upgrade their technologies, extend the industry chain, and strengthen international cooperation and exchanges to promote the sustained and healthy development of the needle coke industry.

Ms. Wan Hongli, Business Manager at Beijing Longyue Mining Co., Ltd., delivered a keynote speech on "Analysis of China's Graphite Electrode Exports".

In her speech, she comprehensively analyzed the current status of China's graphite electrode exports, market supply and demand, the industry chain, the status of overseas manufacturers, export challenges and opportunities, as well as future prospects. She pointed out that the market price of graphite electrodes has been relatively stable in the past year, and profitability in 2024 has slightly improved compared to 2023. In recent years, overseas manufacturers have been continuously lowering prices, and Chinese exports and overseas manufacturers' products are increasingly converging in terms of quality and price. She predicts that by 2030, the size of the global graphite electrode market will grow by 5.8% compared to 2024.

Guo Mingcong, Deputy Director of the Functional Materials Business Unit at Anshan Thermal Energy Research Institute Co., Ltd. of Sinosteel Corporation, shared insights on "Research and Application of Raw Materials for Special Graphite Materials".

Ms. Guo pointed out that the production cycle of special graphite is relatively long, and the stability requirements during the firing process are high. The production process is crucial for manufacturing special graphite. The control of needle coke and pitch, which are the aggregates used in special graphite, is key to producing high-quality special graphite. With the rapid development of industries such as photovoltaics, new energy batteries, rare earths, smelting, and nuclear power, the demand for special graphite in the market is continuously increasing. Among them, the market potential for photovoltaics, batteries, rare earths, and the nuclear industry will also accelerate and explode. Data shows that in 2023, the global market size for special graphite was approximately USD 1.74 billion, and it is expected to reach USD 2.05 billion by 2028, with a compound annual growth rate (CAGR) of 3.3% from 2023 to 2028.

Mr. Qian Yi, Senior Researcher at ICCSINO, delivered a keynote speech on "Analysis of the Driving Forces Behind the Increase in the Proportion of Electric Arc Furnace Steel".

In his speech, he conducted an in-depth analysis of changes in electric arc furnace steel production, supply and demand in the graphite electrode market, operating status of overseas electrodes, driving forces for the development of electric arc furnace steel, and future prospects.

He pointed out that whether it's the rebound in production, the increase in the proportion of ultra-high-power (UHP) electrodes, or the resumption of overseas electrode production, all three aspects indicate that electric arc furnace steel has "gradually emerged from the trough". However, the market still feels relatively weak, mainly manifested in the "three shortages": shortage of funds, shortage of demand, and shortage of confidence.

For 2025, he predicts that electric arc furnace (EAF) steel will successfully achieve the target of accounting for 15% of total crude steel production, replacing some small blast furnaces in the hinterland. At the same time, the advantages of leading enterprises will continue to expand, while small and medium-sized enterprises will switch flexibly. The demand for anodes, cathodes, and exports will grow overall, and prices are likely to rebound. Furthermore, exports remain a highlight, with overseas steel plants actively adopting EAFs, particularly in countries such as Turkey, the UK, Japan, Korea, Germany, and Algeria.

In the coming years, apart from the EAF steel ratio target in 2025, there will also be driving factors such as the implementation of carbon tax policies in 2026.

At the end of the conference, Ms. Lian Ping, General Manager of Xinluo Information, delivered a keynote report titled "Outlook for Needle Coke in the Lithium Battery Industry in 2025".

In her speech, she analyzed the global battery landscape and provided a comprehensive outlook on the current status and future prospects of the needle coke and anode material markets.

She pointed out that driven by both electric vehicles and energy storage, the global lithium battery market is expected to grow at a compound annual rate of nearly 20%. It is projected that lithium battery production will increase annually from 2023 to 2027E, with an average growth rate of about 18.4%. Driven by lithium batteries, global anode material production is expected to reach 2.1212 million tons in 2024, with China's production reaching 2.0831 million tons. However, as downstream growth slows, the demand for anodes in 2025 will also grow more slowly. It is estimated that the total battery production in 2025 will be 1690GWh, corresponding to a demand for 2.03 million tons of anode materials, and this is expected to reach 3.3 million tons in 2028. Therefore, the market should not be overly pessimistic about the future.

Currently, China's needle coke industry has entered a stage of capacity optimization. It is estimated that China's effective needle coke capacity will be 2.64 million tons in 2028. The supply increment of needle coke in the coming years will mainly come from China, with domestic needle coke supply expected to reach about 1.85 million tons by 2028. Therefore, the price fluctuations of needle coke in the next 2-3 years will mainly be determined by the supply of raw materials such as oil slurry/coal tar and demand, as there is no significant bottleneck in needle coke production capacity itself. The future demand increment for needle coke will continue to be in the lithium battery anode material industry, while the demand from the graphite electrode industry will remain stable with slight growth.

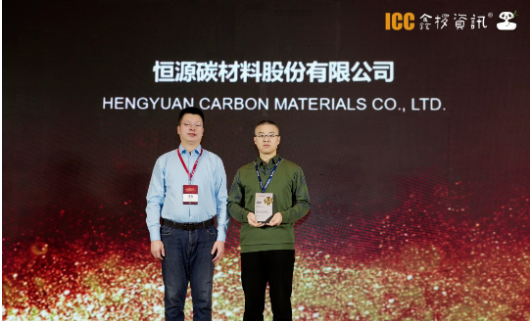

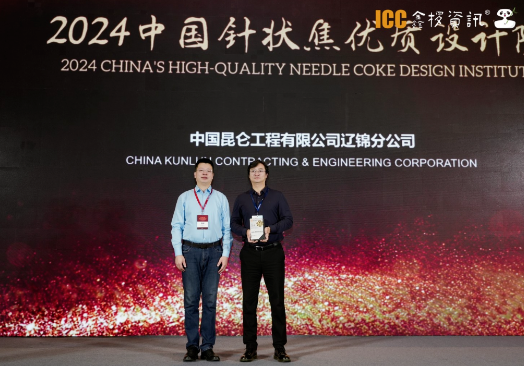

The conference also included an exciting awards ceremony for outstanding enterprises in needle coke, petroleum coke, and graphite electrodes.

Below are the awards and the list of winning enterprises:

2024 Global Needle Coke Quality Brand Awards:

* Shandong Yida New Material Co., Ltd.

* Weifang Fumei New Energy Co., Ltd.

* Shandong Jingyang Technology Co., Ltd.

2024 China Needle Coke Quality Brand Awards:

* Shandong Lianhua New Material Co., Ltd.

* Shandong Yiwei New Material Co., Ltd.

2024 China Needle Coke Emerging Enterprise Award:

* Hengyuan Carbon Material Co., Ltd.

2024 China Needle Coke Quality Design Institute Award:

* China Kunlun Engineering Co., Ltd. Liaojin Branch

2024 China Needle Coke Quality Import & Export Enterprise Awards:

* Tianjin Jinggang Sinbo International Trade Co., Ltd.

* Beijing Fangda Carbon New Material Technology Co., Ltd.

* Daqing Gaoxin International Trade Co., Ltd.

* Shanghai Xinmo Industrial Co., Ltd.

2024 China Petroleum Coke Quality Supplier Awards:

* Dalian Fuli Petrochemical Trade Co., Ltd.

* Shandong Huamao Holding Group

* Daqing Gaoxin International Trade Co., Ltd.

2024 Global Graphite Electrode Excellence Brand Awards:

* Fangda Carbon New Material Technology Co., Ltd.

* Jilin Carbon Co., Ltd.

* Liaoning Dantan Technology Group Co., Ltd.

* Jianglong Carbon Group

* Zhongzhou Carbon Co., Ltd.

* Kaifeng Pingmei New Carbon Material Technology Co., Ltd.

* Yingkou Desheng Carbon Co., Ltd.

2024 China Graphite Electrode Excellence Brand Award:

* Qinghai Shengxiang Electrode Products Co., Ltd.

2024 China Graphite Electrode Export Achievement Awards:

* Henan Huaruo Import & Export Trade Co., Ltd.

* Beijing Longyue Mining Co., Ltd.

2024 Excellent Suppliers of Intelligent Equipment for New Carbon Materials:

* Shanghai Qigao Valve Manufacturing Co., Ltd.

* Hunan Huaxia Special Transformer Co., Ltd.

* Xinxiang Huaruide Environmental Protection Technology Co., Ltd.

* Luoyang Jianguang Special Equipment Co., Ltd.

On the 15th, ICCSINO organized participants to visit the Yunnan BTR factory.

The successful hosting of this forum not only built an important platform for cooperation and exchange in the carbon industry but also injected new vitality into promoting technological progress and industrial upgrading in the carbon industry. Participants expressed that they would bring back the insights gained from the forum to their respective workplaces and contribute to the development of the carbon industry.

Looking ahead, with the booming development of the new energy industry and the continuous promotion of carbon peaking and carbon neutrality goals, the needle coke and carbon material sectors will face more opportunities and challenges. We believe that with the joint efforts of all colleagues, the carbon industry will surely embrace a brighter future. Here, we thank all the guests and representatives who participated in this forum and look forward to gathering again in future forums to witness the glorious achievements of the carbon industry!

CONTACT US

CONTACT US ICC APP

ICC APP